Floating Floors vs. Glued Floors

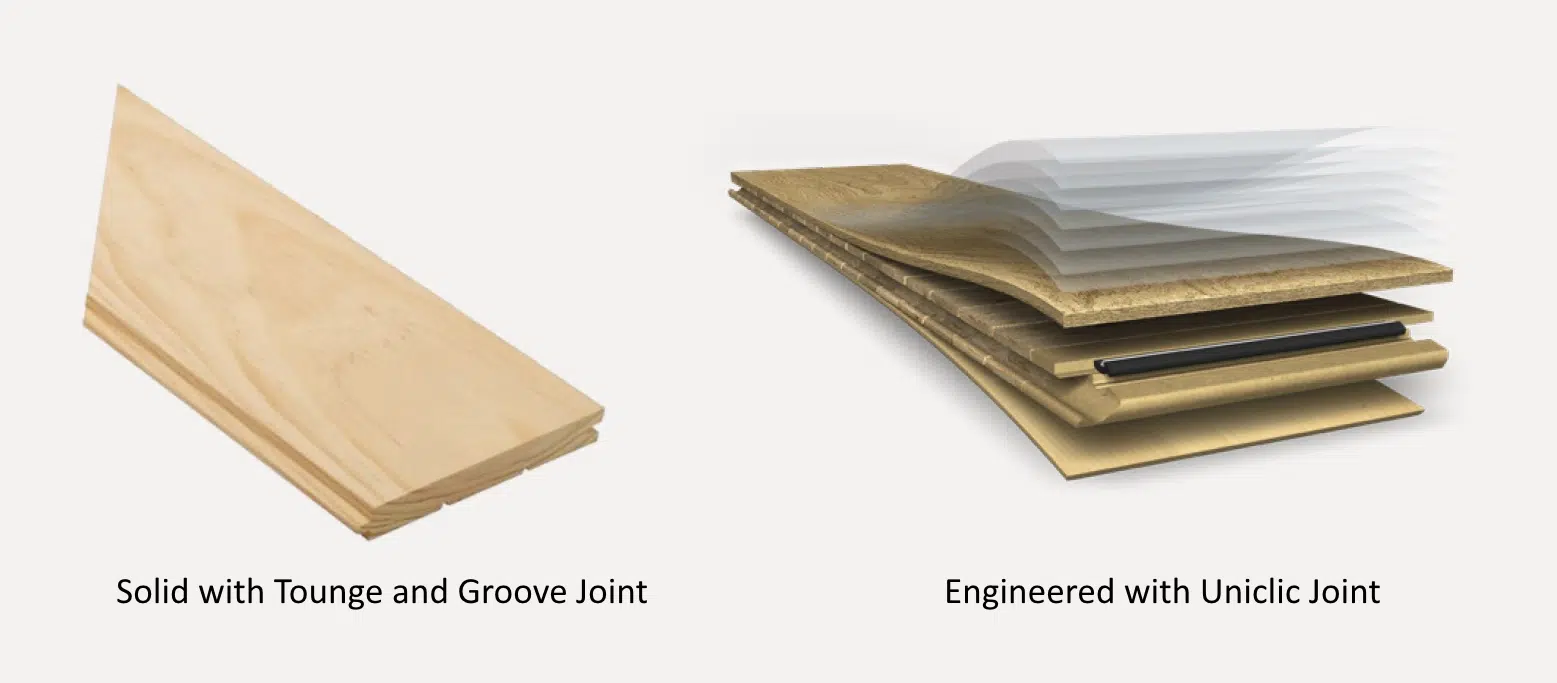

Choosing the right flooring for your space involves careful consideration of practicality, aesthetics, and budget. In recent times, floating floors have surged in popularity, especially with dedicated brands like Quickstep and Pergo engineered for this installation method. However, it’s crucial to delve into the key distinctions between floating vs glued floors, especially as some flooring brands not initially designed for floating are being installed as such to cut costs.

Floating Floors: A Cost-Effective Alternative

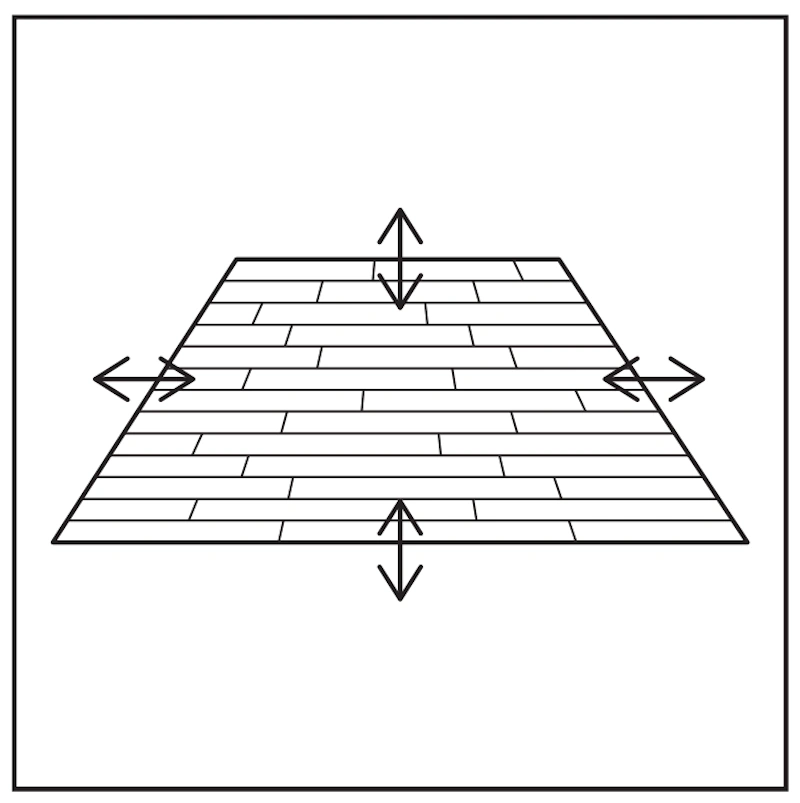

Floating floors, gracefully floating over an underlayment without direct attachment to the subfloor, have gained popularity. Brands like Quickstep and Pergo are purposefully engineered for floating installations, offering a cost-effective and efficient solution for homeowners. Here’s why:

1. Installation Cost:

Floating floors generally require less labor and materials, making them more budget-friendly compared to glued down floors.

2. Repair Options:

Quickstep and Pergo offer expanded repair options when floated. If a specific area is damaged, homeowners can replace planks without affecting the entire floor, saving both time and repair costs.

3. Moisture Barrier:

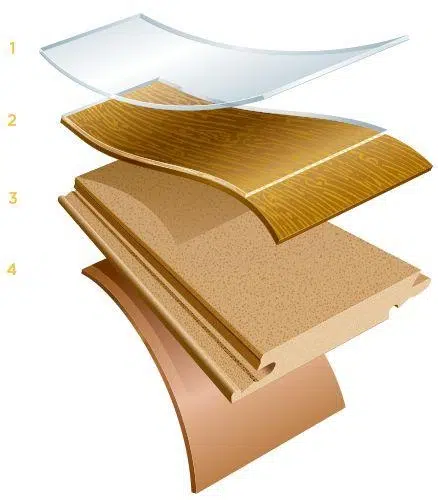

Floating floors, including Quickstep and Pergo, are installed with underlays. Good quality underlays incorporate a Damp-Proof Membrane (DPM). This eliminates the need for a separate and often costly moisture barrier, enhancing overall budget-friendliness.

4. Earthquake Resilience:

Floating floors can be advantageous in earthquake-prone areas. Decoupled from the subfloor, they are less affected by minor damages to the subfloor caused by seismic activity, making them a practical choice for regions with frequent seismic events.

Preventing Gapping Issues:

Gapping between floorboards can be a concern, especially in areas with fluctuating humidity levels. Quality floating floors, such as those from Quickstep and Pergo, are designed to mitigate gapping issues:

1. Quality Underlay:

Choosing a high-quality underlay is crucial in preventing gapping. A premium underlayment can absorb sound, provide thermal insulation, and prevent gaps from forming.

2. Engineered Design:

Quickstep and Pergo, as reputable brands, incorporate innovative engineering to minimize the impact of seasonal movement on the floor, ensuring a more stable and gap-resistant flooring solution.

Glued Down Floors: Limitations in Repair and Seasonal Movement

While glued down floors have their merits, they come with limitations that should be considered:

1. Installation Challenges:

Installing glued down floors is more costly and time-consuming, requiring drying time and moisture barriers over concrete subfloors, contributing to increased expenses and a longer installation timeline.

2. Limited Repair Options:

Repairing glued down floors can be challenging. If damage occurs, it often involves costly plank removal, reapplication of moisture barriers, and sometimes requires sanding and refinishing of the entire floor, leading to higher repair costs.

3. Seasonal Movement:

Glued down floors may experience gapping during seasonal changes, and once gaps appear, there’s little that can be done to rectify the issue.

Conclusion:

In the ongoing debate between floating floors and glued down floors, it’s crucial to weigh the advantages and disadvantages of each installation method. Brands like Quickstep and Pergo, designed specifically for floating installations, offer cost-effective solutions with enhanced repair options, preventive measures against gapping, and additional resilience in earthquake-prone areas. While glued down floors have their place, especially in specific settings, the growing popularity of floating floors suggests that the benefits they provide, including lower installation costs and improved repair options, make them a viable choice for many homeowners.